At JAYCE Consulting, we recognize that thriving in today’s fast-paced market necessitates more than just adopting the latest technologies. It requires a strategic approach to technology integration that enhances your operations, drives innovation, and fosters sustainable growth. Our comprehensive technology integration and innovation process is designed to help your business leverage state-of-the-art tools and methodologies to achieve exceptional results.

Our Technology Integration and Innovation Approach

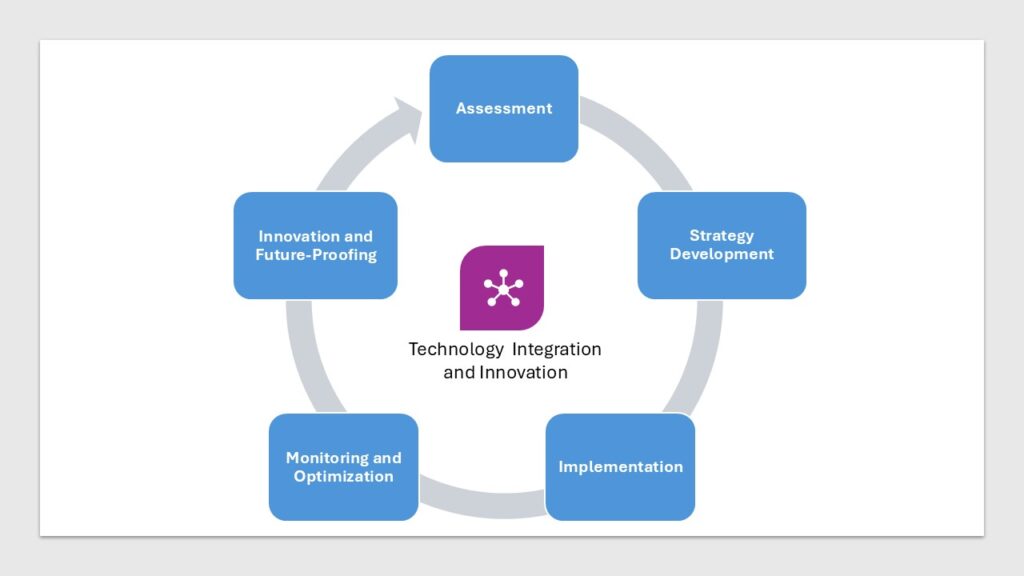

JAYCE Consulting ensures that technology integration and innovation are strategically aligned with business objectives, leading to sustainable growth and competitive advantage.

Our Process

1. Assessment

Objective: Understand the current technological landscape and identify opportunities for improvement.

- Technology Audit: Conduct a comprehensive review of existing technologies, systems, and processes.

- Gap Analysis: Identify gaps and inefficiencies in the current setup.

- Stakeholder Interviews: Engage with key stakeholders to understand pain points and gather insights.

2. Strategy Development

Objective: Develop a customized technology integration plan that aligns with business goals.

- Solution Mapping: Identify the best technologies and tools that fit the organization’s needs.

- Roadmap Creation: Develop a step-by-step implementation plan with clear milestones and timelines.

- Resource Allocation: Determine the resources (time, budget, personnel) required for successful implementation.

3. Implementation

Objective: Seamlessly integrate new technologies into existing processes.

- Pilot Programs: Start with small-scale pilots to test the new technologies and gather feedback.

- Full-Scale Deployment: Roll out the technology across the organization, ensuring minimal disruption.

- Training and Support: Provide comprehensive training for staff and ongoing support to ensure smooth adoption.

4. Monitoring and Optimization

Objective: Ensure the new technologies deliver the desired outcomes and continually optimize for improvement.

- Performance Metrics: Establish key performance indicators (KPIs) to measure the success of the integration.

- Continuous Monitoring: Regularly monitor the performance of the new systems and technologies.

- Feedback Loop: Gather feedback from users and stakeholders to identify areas for further improvement.

5. Innovation and Future-Proofing

Objective: Foster a culture of continuous innovation and ensure the technology remains up-to-date.

- R&D Investment: Allocate resources for research and development to stay ahead of technological trends.

- Scalability: Ensure the technology infrastructure can scale with the business’s growth.

- Future Planning: Regularly review and update the technology strategy to align with changing business needs and market conditions.

Key Benefits

- Enhanced Efficiency: Optimize operations and processes with advanced technological solutions.

- Innovation Leadership: Cultivate a culture of innovation, positioning your business ahead of the competition.

- Cost Savings: Lower operational costs through automation and streamlined workflows.

- Improved Decision-Making: Utilize data-driven insights for superior strategic planning and execution.

- Scalable Solutions: Implement adaptable technology solutions that grow with your business.

Success Story: Harnessing Technology and Innovation to Reduce Scrap Rates

Our client faced a significant challenge with excessive scrap generation on a high-volume part produced using internal gas processes. The part was manufactured in multiple colors, and a critical issue was the inability to accurately verify the correct location of the gas channel. This led to inconsistencies and a high scrap rate.

JAYCE Consulting was engaged to evaluate the situation and implement effective countermeasures. Our team conducted a series of Design of Experiments (DOE) to analyze the processing variables and identify the root causes of the issues. Based on our findings, we developed a robust solution that optimized the gas channel placement and minimized scrap.

Additionally, we introduced a thermal imaging camera as a redundancy measure. This technology allows for real-time verification of acceptable parts before they reach the machine operator, ensuring quality and consistency. The implementation of these innovations not only reduced scrap rates significantly but also enhanced overall production efficiency and reliability

Ready to Propel Your Business Forward?