Drive your business forward with JAYCE Consulting’s continuous improvement services. Our expert team is dedicated to helping you achieve sustained operational excellence and fostering a culture of ongoing enhancement.

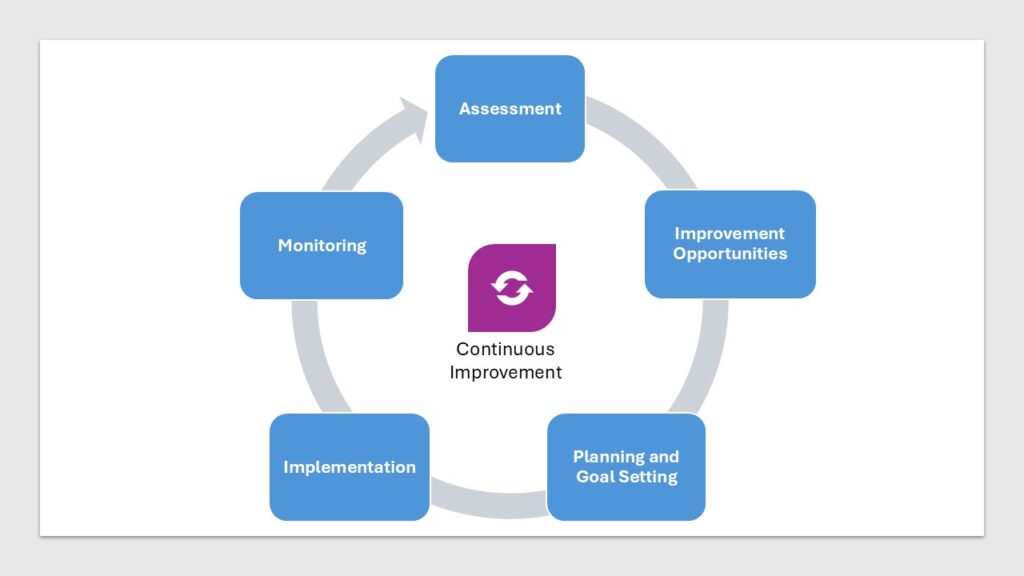

Our Continuous Improvement Approach

At JAYCE Consulting, we follow a structured approach to continuous improvement, ensuring that every aspect of your operations is continually analyzed and enhanced for long-term success.

Step-by-Step Process

- Assessment and Baseline Setting

- Initial Assessment: Conducting a thorough assessment of current operations.

- Performance Metrics Establishment: Setting up key performance indicators.

- Baseline Analysis: Establishing baseline performance levels.

2. Identifying Improvement Opportunities

- Root Cause Analysis: Identifying the root causes of inefficiencies.

- Opportunity Identification: Spotting areas for improvement.

- Prioritization: Ranking improvement opportunities.

3. Planning and Goal Setting

- SMART Goals Development: Creating specific, measurable, achievable, relevant, and time-bound goals.

- Action Plan Creation: Developing detailed action plans.

- Resource Allocation: Allocating necessary resources.

4. Implementation and Execution

- Pilot Projects: Testing improvement initiatives on a small scale.

- Standardization of Best Practices: Implementing best practices organization-wide.

- Change Management: Facilitating smooth transitions.

5. Monitoring and Sustaining Improvement

- Performance Tracking: Continuously monitoring performance metrics.

- Feedback Loops: Incorporating feedback for ongoing improvement.

- Continuous Feedback and Adjustment: Making adjustments based on continuous feedback.

Benefits of Continuous Improvement

- Enhanced Operational Efficiency

- Improved Quality and Consistency

- Reduced Costs

- Increased Employee Engagement

- Sustained Competitive Advantage

Success Story: Reducing Scrap and Boosting Efficiency

One of our clients faced a significant challenge with high scrap rates for a particular molded part. The internal scrap was averaging between 15% and 20%, resulting in an annualized cost of approximately $127,000 in scrap alone. Seeking a solution, they reached out to JAYCE Consulting for assistance.

Utilizing our proven process for Continuous Improvement, our team dove into the problem with a commitment to finding a sustainable and efficient solution. Through a combination of meticulous analysis and innovative strategies, we successfully reduced the scrap rate to less than 3% annually. This not only saved our client substantial costs in scrap dollars but also minimized customer returns, enhancing overall customer satisfaction. Our approach not only resolved the immediate issue but also equipped the client with tools and processes to maintain this improved performance in the long term.

Ready to Implement Continuous Improvement?

Empower your business with JAYCE Consulting’s tailored continuous improvement solutions. Contact us today for a consultation and start your journey towards sustained operational excellence.