Transform Your Operations

Unlock the full potential of your business with JAYCE Consulting’s process optimization services. Our expert team is dedicated to enhancing efficiency, reducing costs, and driving sustainable growth through innovative and tailored solutions.

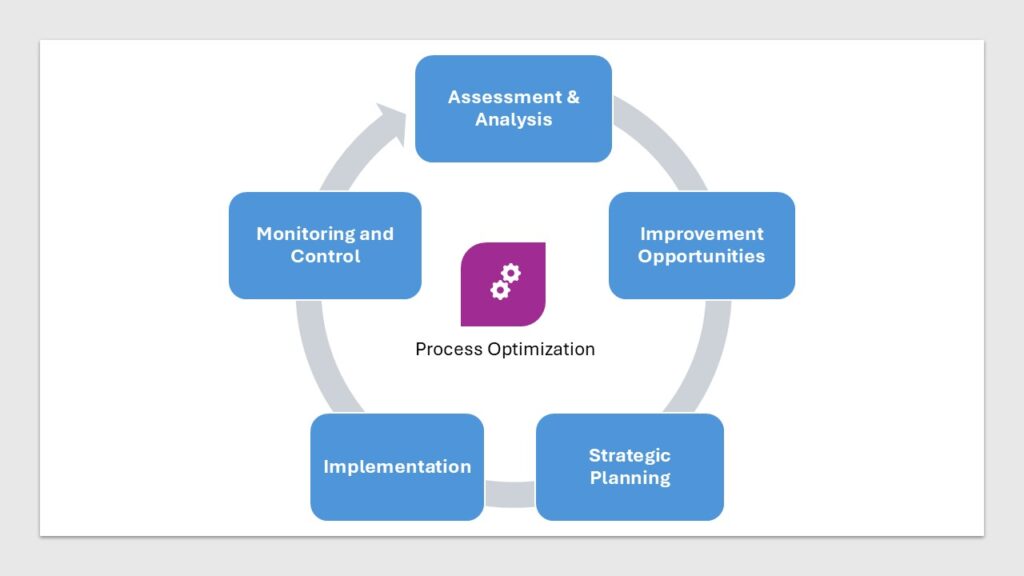

Our Process Optimization Framework

At JAYCE Consulting, we follow a structured approach to process optimization, ensuring that every aspect of your operations is thoroughly analyzed and improved for maximum efficiency and profitability.

Step-by-Step Process

Assessment and Analysis

- Data Collection: Gathering comprehensive data on current processes.

- Process Mapping: Visualizing workflows to identify inefficiencies.

- Benchmarking: Comparing against industry standards.

Identifying Improvement Opportunities

- Root Cause Analysis: Understanding underlying issues.

- Value Stream Mapping: Eliminating non-value-added activities.

- Prioritization: Ranking improvement opportunities.

Strategic Planning

- Goal Setting: Defining clear objectives.

- Resource Allocation: Determining necessary resources.

- Timeline Development: Establishing a realistic timeline.

Implementation

- Pilot Testing: Conducting pilot tests for validation.

- Process Redesign: Implementing best practices.

- Change Management: Facilitating smooth transitions.

Monitoring and Control

- Performance Tracking: Monitoring performance using KPIs.

- Regular Audits: Conducting regular reviews.

- Continuous Improvement: Encouraging ongoing feedback.

Benefits of Process Optimization

- Increased Efficiency

- Enhanced Quality

- Cost Savings

- Agility and Adaptability

Success Story: Mastering Process Optimization for New Molds and Materials

Our client faced significant challenges in optimizing the process for newly acquired molds on their 3000 Ton injection molding machine. Compounding the complexity, they were also processing an unfamiliar material and incorporating internal gas into the procedure for the first time. These technical hurdles were causing delays and inefficiencies, prompting the client to seek expert assistance.

JAYCE Consulting stepped in, applying our proven Process Optimization methodology. Our team meticulously analyzed the situation, addressing the technical issues related to the new molds, unfamiliar material, and gas usage. Through our systematic approach, we identified the root causes of the instability and implemented solutions to streamline the process.

As a result, we successfully brought the process to a steady state, ensuring consistent quality and efficiency. This not only resolved the immediate issues but also equipped the client’s team with the knowledge and confidence to manage similar challenges in the future. Our intervention not only optimized the current process but also set the foundation for ongoing operational excellence

Ready to Optimize Your Processes?

Empower your business with tailored process optimization solutions from JAYCE Consulting. Contact us today for a consultation and start your journey towards operational excellence.